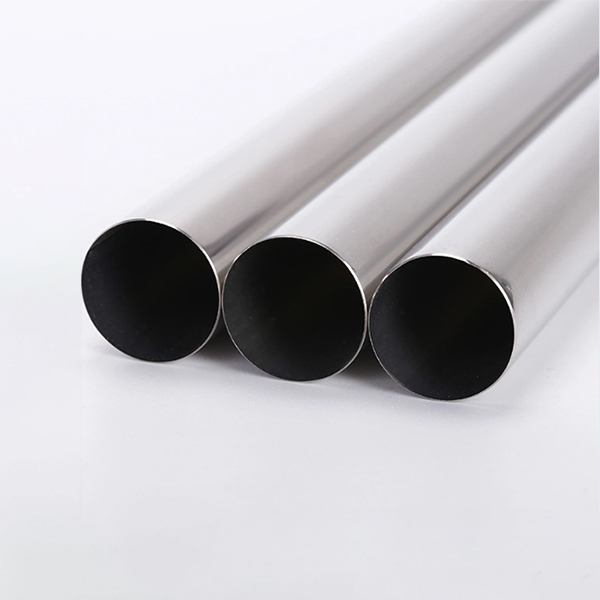

ʻO TA2 titanium alloy tube no ka hana ʻoihana

TA2 Titanium Alloy Pipe, Nā Pono

TA2 Titanium Alloy Pipe, Hoʻohālikelike ʻia me nā mea metala ʻē aʻe, loaʻa iā ia nā pono aʻe:

1. ʻO ka ikaika kiko'ī kiʻekiʻe (ikaika/density) (e nānā i ke kiʻi), hiki i ka ikaika tensile ke piʻi i 100 ~ 140kgf / mm2,ʻoiaiʻo 60% wale nō ka nui o ke kila.

2. He maikaʻi ka ikaika o ka mahana wela, ʻoi aku ka nui o ka mahana o ka hoʻohana ʻana ma mua o ka alumini alumini, ma ka mahana wela hiki ke mālama i ka ikaika i koi ʻia, hiki ke hana ma 450 ~ 500 ℃ wela no ka manawa lōʻihi.

3. ʻO ke kūpaʻa corrosion maikaʻi, ka ʻili o ka titanium i ka lewa i hoʻokumu koke ʻia i kahi ʻāpana o ke kiʻi ʻoniʻoni a me ka dense oxide, hiki ke pale i nā ʻano o ka erosion media.Loaʻa i ka Titanium ke kūpaʻa ʻino maikaʻi i ka oxidizing a me ka neutral media, ʻoi aku hoʻi i ka wai kai, wai chlorine a me nā hāʻina chloride.Akā i ka hoʻohaʻahaʻa ʻana, e like me ka hydrochloric acid solution, ʻilihune ka titanium corrosion resistance.

4. Hiki ke mālama i nā mea hoʻoheheʻe Titanium me ka hana haʻahaʻa haʻahaʻa haʻahaʻa a me nā mea hoʻomaʻemaʻe haʻahaʻa haʻahaʻa, e like me TA7, ke mālama i kekahi plasticity ma -253 ℃.

5. Low elastic modulus, liʻiliʻi thermal conductivity, ʻaʻohe ferromagnetism.

6. Paʻakikī kiʻekiʻe.

7. Ka waiwai stamping maikaʻi a me ka thermoplasticity maikaʻi.

Hiki ke loaʻa i ka hoʻomaʻamaʻa wela ʻo Titanium alloy ke ʻano ʻokoʻa a me ka microstructure ma o ka hoʻoponopono ʻana i ka hana mālama wela.Manaʻo maʻamau ʻo ka microstructure equiaxed maikaʻi he plasticity maikaʻi, kūpaʻa wela a me ka ikaika luhi.ʻOi aku ka ikaika o ka acicular, ka ikaika creep a me ka paʻakikī o ka haki.ʻOi aku ka maikaʻi o nā mea hoʻohuihui equiaxed a me acicular.

ʻO TA2 Titanium Alloy Pipe, ʻO nā ʻano hana lapaʻau maʻamau i hoʻohana ʻia he annealing, hoʻonā a me ka mālama ʻana i ka wā kahiko.ʻO ka Annealing ka mea e hoʻopau ai i ke koʻikoʻi o loko, hoʻomaikaʻi i ka plasticity a me ka microstructure stability, i mea e loaʻa ai nā waiwai piha.ʻO ka mea maʻamau, ʻo ka mahana hoʻohuihui o ka α alloy a me (α+β) alloy he 120 ~ 200 ℃ ma lalo o ka wahi hoʻololi o (α+β) -- →β phase.ʻO ka hopena a me ka mālama ʻana i ka wā kahiko, ʻo ia ka loaʻa ʻana o ka α 'phase a me ka metastable β phase o martensite ma ka hoʻomaloʻo wikiwiki ʻana i ka ʻāina wela kiʻekiʻe, a laila e hoʻoheheʻe i kēia mau ʻāpana metastable ma ka paʻa ʻana i ka ʻāpana wela waena, a loaʻa ka maikaʻi i hoʻopuehu ʻia nā ʻāpana lua. , e like me ka α phase a i ʻole ka hui ʻana, e hoʻokō ai i ke kumu o ka hoʻoikaika ʻana i ka alloy.ʻO ka mea maʻamau (alpha + beta) e hoʻopiʻi ana i nā huila i loko o ka alpha + beta) -- - > ka helu hoʻololi o ka pae beta ma lalo o 40 ~ 100 ℃, ka hoʻoheheʻe ʻana i ka metastable beta alloy ma ka alpha + beta) -- - > wahi hoʻololi ʻāpana beta ma luna o 40 ~ 80 ℃.ʻO ka mahana o ka wā kahiko he 450 ~ 550 ℃.Eia kekahi, i mea e hoʻokō ai i nā koi kūikawā o ka mea hana, hoʻohana pū ka ʻoihana i ka annealing pālua, isothermal annealing, β wela wela, deformation wela wela a me nā kaʻina hana wela metala.

TA2 Titanium Alloy Pipe, Hoʻokaʻawale

ʻO ka paipu Titanium, ka paipu hoʻoheheʻe titanium, ka titanium splicing tee, ka titanium splicing kuʻekuʻe, ke apo hoʻoheheʻe titanium, ka hōʻemi ʻana o ka titanium, ka titanium tee, ka kuʻekuʻe titanium, ka chimney titanium, etc.

TA2 Titanium Alloy Pipe, Ke Kumu Hana O

ʻO TA2 Titanium Alloy Pipe, ʻo ka hoʻopili ʻana i nā ʻano mea like ʻole o ka pipeline titanium, i hoʻohana ʻia no ka neʻe ʻana o nā mea ma waena o nā ʻano mea like ʻole, ʻo ka pipeline ka pale ʻana o nā mea titanium ponoʻī, i mea e hoʻololi ai i ka pipeline maʻamau no ka pipeline maʻamau ʻaʻole hiki ke hoʻokō i ka koi. .ʻO ka maʻamau ф 108 ma luna he paipu wili.

Nā Kūlana Kūlana Nui

| DN(mm)) | Ke ana ana i ke anawaena o waho (mm) | ʻO ka mea |

| 15 | 18 | TA2 |

| 20 | 25 | TA2 |

| 25 | 32 | TA2 |

| 32 | 38 | TA2 |

| 40 | 45 | TA2 |

| 50 | 57 | TA2 |

| 65 | 76 | TA2 |

| 80 | 89 | TA2 |

| 100 | 108 | TA2 |

| 125 | 133 | TA2 |

| 150 | 159 | TA2 |

| 200 | 219 | TA2 |

| 250 | 273 | TA2 |

| 300 | 325 | TA2 |

| 350 | 377 | TA2 |

| 400 | 426 | TA2 |

| 450 | 480 | TA2 |

| 500 | 530 | TA2 |

| 600 | 630 | TA2 |

Hōʻike Huahana