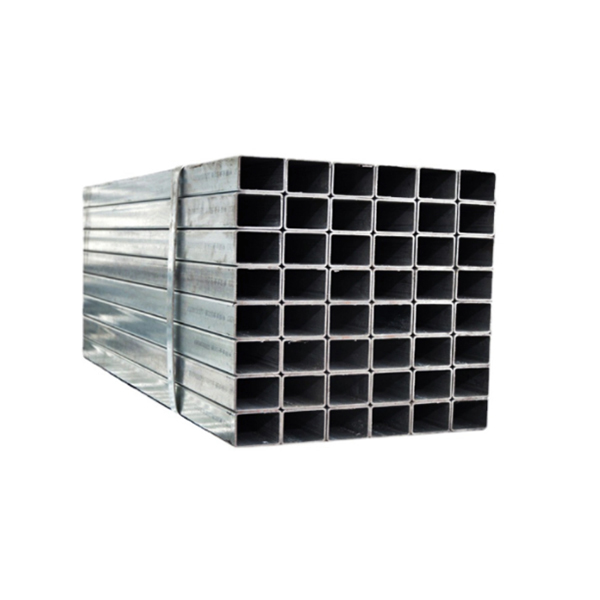

He paipu hao kuhiliʻole pōʻai

ʻO nā hiʻohiʻona o nā mea 304 mea paipu kila kila

1. ʻO ka paipu kila kila i hanaʻia i ka 304 he mea maikaʻi loa ia, palekana a hilinaʻi hoʻi e hoʻohana.

2. Hiki i ka 304 stainless steel paipu ke kulou me ka hana nui Gini i ka nui.Ua ʻike mākou e pili pinepine ka ʻenehana hana i ka paipu kila kila, akā e hoʻokō nā limahana i ke kūkulu ʻana e like me ka super distortion o ka paipu kila kila.

3. ʻO ka 304 stainless steel paipu i ʻoi aku ka maikaʻi o ka pale ʻana i ka ʻakika a me ka ʻino alkali.Aia kekahi kiʻiʻoniʻoni pale lahilahi ma ka ʻili o waho o ka paipu kila kila, akā paʻakikī loa.ʻOiai inā ua pōʻino ka paipu kila kila, ʻoiai aia ka oxygen a puni ia.

4. He māmā loa ka maikaʻi o ka paipu stainless steel 304, no laila ua maʻalahi ka lawe ʻana a hoʻokomo iā ia, e hōʻemi nui ana i ke kumukūʻai o ka papahana.

ʻO nā waiwai mīkini a me nā hiʻohiʻona o nā paipu kila kila

ʻO ke kila kila ʻole ke kila i kū ʻole i nā media corrosive nāwaliwali e like me ka ea, ka mahu, a me ka wai, a me nā mea hoʻoheheʻe kemika e like me ka waikawa, ka alkali, a me ka paʻakai, i ʻike ʻia hoʻi ʻo ke kila kūwaho.Ma nā hoʻohana pono, kapa pinepine ʻia ke kila kūʻē i ka media corrosive nāwaliwali, a ʻo ke kila kūʻē i ka media chemical corrosion ua kapa ʻia ʻo ka acid-resistant steel.Ma muli o ka ʻokoʻa o ka haku mele ʻana ma waena o nā mea ʻelua, ʻaʻole kū pono ka mea mua i ka corrosion media kemika, ʻoiai ʻo ka mea maʻamau he stainless.ʻO ka pale ʻana i ka corrosion o ke kila kila ma muli o nā mea hoʻohui i loko o ke kila.

ʻO nā hiʻohiʻona nui o ke kila kila:

1.Weldability

Loaʻa nā koi like ʻole o ka hoʻohana ʻana i nā huahana no ka hana welding.ʻAʻole pono ka papa papaʻaina i ka hana welding, a komo pū kekahi mau ʻoihana ipuhao.Eia nō naʻe, ʻo ka hapa nui o nā huahana e koi i ka hana kuʻi ʻana maikaʻi o nā mea maka, e like me ka papa papa ʻelua, nā kīʻaha thermos, nā paipu kila, nā mea hoʻomehana wai, nā dispenser wai, etc.

2. ʻO ke kūpaʻa ʻino

ʻO ka hapa nui o nā huahana kila kila maikaʻi ke kūʻē i ka corrosion, e like me ka papa ʻaina papa I a me II, nā mea kīhini, nā mea hoʻomehana wai, nā mea hoʻokaʻawale wai, a me nā mea ʻē aʻe. a ninini ma hope o kekahi manawa.Wehe i ka hoʻonā, holoi a maloʻo, a kaupaona i ka pohō kaumaha e hoʻoholo ai i ke kiʻekiʻe o ka ʻinoʻino (E hoʻomanaʻo: Ke hoʻomaʻamaʻa ʻia ka huahana, ʻo ka ʻike Fe i loko o ka lole abrasive a i ʻole ke one e hoʻoulu ai i nā kiko ʻōpala ma ka ʻili i ka wā o ka hoʻāʻo ʻana).

3. ʻO ka hana hoʻopololei

I ka nohona o kēia mau lā, hoʻomaʻamaʻa pinepine ʻia nā huahana kila kila i ka wā o ka hana ʻana, a he liʻiliʻi wale nō nā huahana e like me nā mea hoʻomehana wai a me ka liner dispenser wai ʻaʻole pono i ka polishing.No laila, pono kēia i ka hana polishing o ka mea maka.ʻO nā kumu nui e pili ana i ka hana polishing penei:

① nā hemahema o nā mea maka.E like me ka ʻōpala, ka lua, ka pickling, etc.

②Ka pilikia o nā mea maka.Inā haʻahaʻa loa ka paʻakikī, ʻaʻole maʻalahi ka poni i ka wā e hoʻoliʻi ai (ʻaʻole maikaʻi ka waiwai BQ), a inā haʻahaʻa loa ka paʻakikī, maʻalahi ka ʻike ʻana o ka ʻili ʻalani ma ka ʻili i ka wā kiʻi hohonu. ka waiwai BQ.He maikaʻi nā waiwai BQ me ka paʻakikī kiʻekiʻe.

③ No ka huahana huki hohonu, e ʻike ʻia nā wahi ʻeleʻele liʻiliʻi a me RIDGING ma ka ʻili o ka wahi me ka nui o ka deformation, no laila e pili ana i ka hana BQ.

4. Kūleʻa wela

ʻO ke kūpaʻa wela, ʻo ia hoʻi, hiki i ke kila kuhili ke hoʻomau i kona ʻano kino maikaʻi a me nā ʻano mechanical i nā wela kiʻekiʻe.

Ka hopena o ke kalapona: Hoʻokumu ikaika ʻia ke kalapona a hoʻopaʻa ʻia i nā kila kuhili ʻole austenitic.Nā mea e hoʻoholo ai i ka austenite a hoʻonui i ka ʻāina austenite.ʻO ka hiki o ke kalapona ke hana i ka austenite ma kahi o 30 mau manawa ma mua o ka nickel, a ʻo ke kalapona kahi mea interstitial e hiki ke hoʻonui nui i ka ikaika o ka austenitic stainless steel ma o ka hoʻoikaika ʻana i ka hopena paʻa.Hiki i ke kalapona ke hoʻomaikaʻi i ke koʻikoʻi o ka corrosion kū'ē o austenitic stainless steel i loko o ka chloride concentrated (e like me 42% MgCl2 boiling solution).

Eia nō naʻe, i ka austenitic stainless steel, ʻike pinepine ʻia ke kalapona ma ke ʻano he mea pōʻino, no ka mea ma lalo o kekahi mau kūlana (e like me ka welding a i ʻole ka hoʻomehana ʻana ma 450 ~ 850 ° C) i ke kūpaʻa corrosion o ke kila kila, hiki i ke kalapona ke launa pū me ke kalapona i ka. kila.Hoʻokumu ʻo Chromium i nā pūhui kalapona ʻano kiʻekiʻe-chromium Cr23C6, e alakaʻi ana i ka hoʻopau ʻana o ka chromium kūloko, kahi e hōʻemi ai i ke kūpaʻa corrosion o ke kila, ʻoi aku ka pale ʻana i ka intergranular corrosion.nolaila.ʻO ka hapa nui o nā chromium-nickel austenitic stainless steels i kūkulu hou ʻia mai ka makahiki 1960 he mau ʻano kalapona ultra-haʻahaʻa me kahi ʻano kalapona ma lalo o 0.03% a i ʻole 0.02%.Hiki ke ʻike ʻia e like me ka emi ʻana o ka ʻike kalapona, e emi ana ka maʻalahi o ka corrosion intergranular o ke kila.I ka wa o ka kalapona maʻiʻo ka haʻahaʻa ma mua o 0.02% loaʻa i ka loa maopopo hopena, a me kekahi mau hoʻokolohua i kuhikuhi i ka kalapona hoʻomāhuahua i ka pitting corrosion tendency o chromium austenitic kuhiliʻole kila.Ma muli o ka hopena maikaʻi ʻole o ke kalapona, ʻaʻole pono e hoʻomalu ʻia ka ʻike kalapona e like me ka haʻahaʻa e like me ka hiki i ke kaʻina hoʻoheheʻe ʻana o ke kila kila austenitic, akā i ke kaʻina hana ma hope o ka wela, ka hana anu a me ka mālama ʻana i ka wela e pale ai i ka piʻi ʻana o ke kalapona ma luna. ka ili o ke kila kila a pale aku i ka chromium carbide Precipitate.

5. ʻO ke kūpaʻa ʻino

Ke emi iho ka nui o nā ʻātoma chromium i ke kila ma mua o 12.5%, hiki ke hoʻololi koke ʻia ka mana electrode o ke kila mai ka hiki ʻole a hiki i ka hiki ke koho electrode.Kāohi i ka ʻino electrochemical.

ʻO ke ʻano hoʻomaʻemaʻe o ka paipu kila kuhili ʻole

1. ka hoʻohana mua ʻana o ka solvent hoʻomaʻemaʻe kila ili, ka ʻili o ka mea hoʻoneʻe organik,

2. a laila e hoʻohana i nā mea hana e wehe ai i ka ʻōpala (puʻi uwea), e wehe i ka unahi hoʻokuʻu a i ʻole ke kiʻi ʻana, ka ʻōpala, ka ʻōpala wili, a pēlā aku.

3. ka hoʻohana ʻana i ka pickling.

ʻano pili

ʻEhā mau ala e hoʻopili ai i nā paipu kila kuhili ʻole:

1. Hoʻopili hoʻopaʻa---------Ua māhele ʻia i ka hoʻopā hoʻokahi a me ka paʻi pālua.ʻO ka hoʻopaʻa ʻana ʻelua ke ʻano pili paʻa.E hoʻohana i ka radial shrinkage external force (hydraulic pliers) e hoʻopaʻa i ka paipu ma ka paipu, a e hoʻokuʻu i ka wai o ka O-ring e hoʻokō i ka hopena pili.He maʻalahi ka hana, hoʻopaʻa maikaʻi a hiki ʻole ke wehe.

2. Hoʻohui hoʻonui apo---------E hoʻohana i ka radial contraction external force (hydraulic pliers) e hoʻopaʻa i ka paipu ma ka paipu, a hoʻokuʻu i ka pahu wai o ke apo lāʻau hoʻopaʻa paʻa ākea e hoʻokō i ka hopena pili, hiki ke wehe, paipu. hoʻokomo a hoʻonui i ke apo convex rolling o ka hopena paipu;He laulā ka hana hoʻopaʻa ʻana, a he kiʻekiʻe ke kumukūʻai o ka hoʻolei ʻana i nā paipu paipu.

3. Hoʻohui welded---------Hoʻohana ʻia ke kaʻina hana wela wela e weld i nā ʻāpana hoʻohui ʻelua e hoʻokō i ka hopena o ka pilina.He kiʻekiʻe ka ikaika o ka pilina, a he mea paʻakikī i ka pale kinoea o ka welding seam e hōʻea i ka maʻamau, kahi e maʻalahi ai ka wili wili, e hōʻemi pono i ke ola lawelawe o ka pipeline;ʻO ka maikaʻi o ka hoʻonohonoho ʻana e hilinaʻi nui ʻia i nā mākau o ka poʻe hana welding, a paʻakikī ka maikaʻi e hoʻopaʻa

4. Hoʻopili paʻa ponoʻī--------- hoʻohana mua ʻia no ka hoʻohui ʻana i ka hose plastik liʻiliʻi, hoʻokomo wikiwiki me ka ʻole o nā mea hana.He maʻalahi ka wehe ʻana a leak ka loko o ka interface, a maikaʻi ʻole ka hana sila.